Build Your Ideas Creatively with Sheet Metal Fabrication

With changing times and evolving technology, the ways of building and manufacturing material have evolved. From melting metals in furnaces to shaping a piece of sheet metal into the desired part, we have made progress in a variety of industries. Ranging from aircraft, automotive, construction to consumer products, HVAC, and furniture, we use sheet metal in so many fields. So how do you make such products? We can make such products by using sheet metal fabrication. In this, flat sheets of metal are turned into metal structures or products with the aid of various tools and techniques.

Steel, aluminium, brass, copper are some of the metals that you can make into sheet metal. Due to its low cost and high tensile strength, steel fabrication in Melbourne has a widespread application in many areas. It is a major element in buildings, infrastructure, machines, appliances, tools, weapons, ships, and automobiles.

To obtain the desired parts, you can manipulate the raw material with special tools like the chop saw, band saws, and press brakes. By removing or deforming the material, you can create holes and cut-outs in 2D geometric shape or bend and stretch the sheet numerous times to different angle respectively.

If you need some finely crafted metalwork for your property or for your company, enquire now at Metal Works. We provide customised steel fabrication in Melbourne tailored to your needs. Our highly skilled and professional team would be more than happy to assist you in the best way possible. We take pride in working with precision while delivering accurate solutions through steel fabrication.

Steel, aluminium, brass, copper are some of the metals that you can make into sheet metal. Due to its low cost and high tensile strength, steel fabrication in Melbourne has a widespread application in many areas. It is a major element in buildings, infrastructure, machines, appliances, tools, weapons, ships, and automobiles.

To obtain the desired parts, you can manipulate the raw material with special tools like the chop saw, band saws, and press brakes. By removing or deforming the material, you can create holes and cut-outs in 2D geometric shape or bend and stretch the sheet numerous times to different angle respectively.

Want to know more about the Fabrication Process?

To get an idea about the fabrication method, let us go through the steps involved in it- Cutting

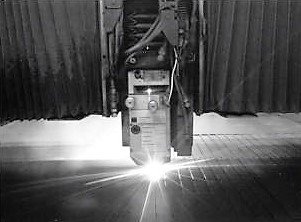

The first step is to cut a large metal sheet into smaller rectangles by applying a shearing force. A straight cut through the sheet can be made by the long blades of the shearing machine. You could use a laser cutter to cut out a more complex shape.

- Bending

You can use a press brake to bend the sheet metal. With proper skill and experience, overbending is used to manage spring back, which is one of the biggest challenges here.

- Assembly

To attain the final product, you need to assemble the pieces together in sheet metal fabrication. They are held in position with clamps or fixture and then welded together successfully. Various advanced welding techniques are used to avoid warping or visual defects.

- Finishing

You need to give your product appropriate finishing, giving it an edge in appearance. Also, it will help in protecting the fabrication against corrosion.

If you need some finely crafted metalwork for your property or for your company, enquire now at Metal Works. We provide customised steel fabrication in Melbourne tailored to your needs. Our highly skilled and professional team would be more than happy to assist you in the best way possible. We take pride in working with precision while delivering accurate solutions through steel fabrication.

Comments

Post a Comment